How might OpenAI's ChatGPT help analyze supply chain shortage news coverage, using GDELT's Web NGrams 3.0 dataset to identify supply chain-related coverage in realtime and analyzing each article through ChatGPT to summarize its contents?

To explore this further, we selected an article about electric vehicle supply chain shortages monitored by GDELT.

Prompt:

You are an AI assistant that summarizes and answers questions about news articles from around the world.

Response:

Yes, I am capable of summarizing and answering questions about news articles and current events. I have been trained on a large corpus of text, including news articles, so I have a good understanding of many different topics and current events. However, please keep in mind that my training data only goes up until 2021, so information on events that have occurred after that may not be available to me.

Prompt:

The article is "[]"

Response:

The global market for lithium-ion batteries is expected to reach $94.15 billion by 2025, largely due to the growth in electric vehicles (EVs). However, the industry faces challenges such as labor and raw material shortages, delays in the construction of gigafactories, and increasing geopolitical tensions. Raw material prices are expected to remain high this year due to a lack of large-scale mining projects. To address these issues, manufacturers are ramping up gigafactory construction and building more efficient supply chains. The EV sector is expected to see strong growth in 2023 due to high gas prices, new EV models, and tax credits, which will drive up demand for batteries. However, current plans for battery capacity expansion may not be enough to meet demand. The batteries market is facing a shortage due to high demand for EVs and a lack of raw materials, particularly lithium. Lithium mining companies are unable to increase supply quickly enough to meet demand, and it will take several years to bring new capacity online. The industry is also facing a new wave of COVID-19 cases in China, which is a major battery manufacturing hub, and is expected to impact battery production in the short to mid-term. To counter these challenges, battery manufacturers may increasingly adopt vertical integration, and the industry is expected to see more investments in its upstream value chain through mergers and joint ventures. There is also a growing trend of demand for lithium iron phosphate batteries, which have improved energy density, longer cycle life, improved safety, lower costs, and do not require nickel and cobalt. Battery recycling is also becoming increasingly important for both the supply chain and the environment.

Prompt:

Does this article describe supply chain shortages?

Response:

Yes, the article describes supply chain shortages as a challenge facing the lithium-ion battery market. The high demand for EVs and a critical lack of raw materials, particularly lithium, have caused a shortage in the batteries market. Lithium mining companies are unable to increase their supply quickly enough to meet the demand, and it will take several years to bring new capacity online. The graphite, a key component in anodes, is also in short supply. The industry is also facing a new wave of COVID-19 cases in China, a major battery manufacturing hub, which is expected to further constrain battery and battery component supplies globally.

Prompt:

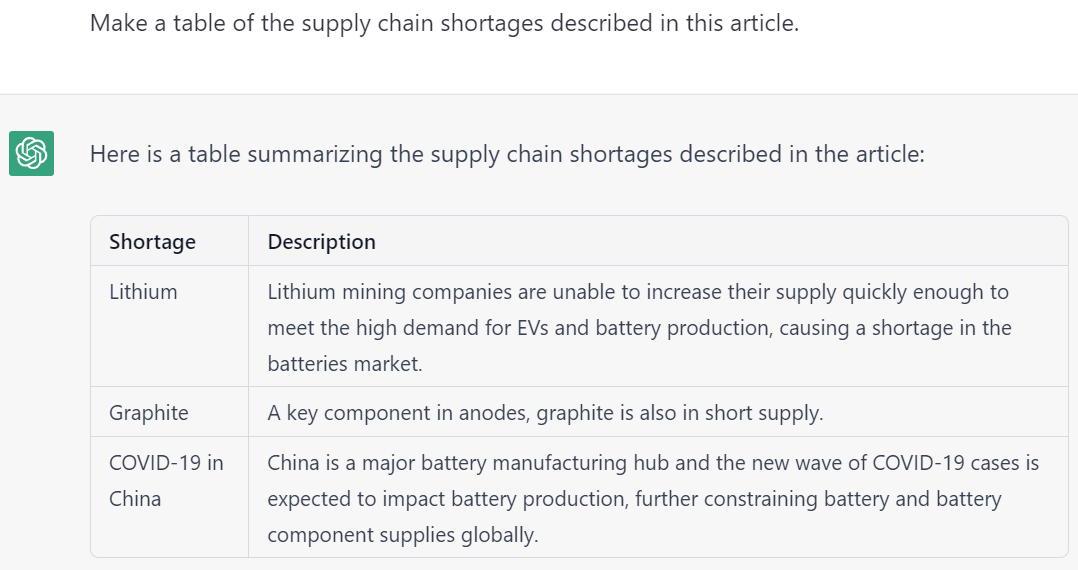

What are the supply chain shortages described in this article?

Response:

The supply chain shortages described in this article are:

-

- Shortage of lithium – Lithium mining companies are unable to increase their supply quickly enough to meet the demand for EVs and battery production, causing a shortage in the batteries market.

- Shortage of graphite – A key component in anodes, graphite is also in short supply.

- Impact of COVID-19 in China – China is a major battery manufacturing hub and the new wave of COVID-19 cases is expected to impact battery production in the short to mid-term, further constraining battery and battery component supplies globally.

Prompt/Response:

Prompt:

What are mitigations to the supply chain shortages described in this article?

Response:

The article mentions several mitigations to the supply chain shortages in the lithium-ion battery market:

-

- Gigafactory construction – Manufacturers are ramping up gigafactory construction to combat the current supply shortage.

- Retaining top talent – Manufacturers are retaining top talent to build more robust and efficient supply chains.

- Vertical integration – Battery manufacturers could increasingly adopt vertical integration to secure their raw materials and maintain more resilient margins.

- Investments in upstream value chain – The industry is expected to see more investments in its upstream value chain as auto and battery manufacturers form mergers and joint ventures, leading to new market dynamics with strategic industry consolidation and more resilient supply chains.

- Lithium refineries and joint ventures – Companies such as Tesla and CATL are expected to begin building lithium refineries and entering joint ventures for the production of battery-grade cathode materials.

- Demand for lithium iron phosphate (LFP) batteries – There is a growing trend of demand for LFP batteries, which are easier to source and do not require the use of nickel and cobalt.

- Battery recycling – Battery recycling is becoming increasingly important as a way to address both supply and environmental issues in the industry. End-of-life EV batteries can be recycled, and the recovered materials can be used in the production of new batteries.

Prompt/Response: